FENC Wins Golden Award for Outstanding Resource Circulation Enterprise with Innovative Green PU Technology

Far Eastern Group R&D Center has been honored with the Golden Award in the Source Management category under Outstanding Resource Circulation Enterprise, presented by the Resource Circulation Administration, Department of Environment, Taiwan, for its TOPGREEN® AirTek PU technology. This prestigious recognition highlights FENC’s excellence in green design and sustainable innovation.

FENC R&D Center EVP Fanny Liao (Right) Received the Award on Behalf of FENC (Photo Credit: FENC)

FENC R&D Center EVP Fanny Liao (Right) Received the Award on Behalf of FENC (Photo Credit: FENC)

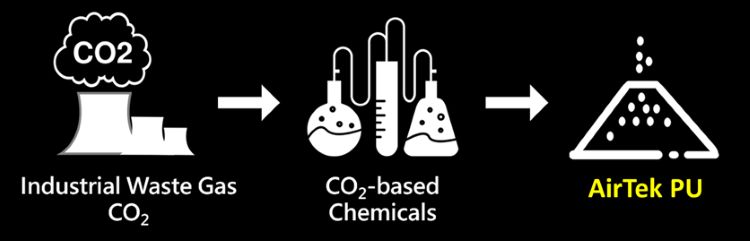

AirTek PU is the world’s first non-isocyanate polyurethane (PU) manufacturing process, utilizing industrial recycled carbon dioxide(CO₂) to replace toxic raw materials. This technology offers a non-toxic, solvent-free, and low-carbon alternative to conventional PU, with 22 international patent applications pending. It also has earned global recognitions, including the ISPO Textrends Award from Germany, the Second Prize of “Best CO₂ Utilisation 2025” for the Innovation Award from Germany, and Taiwan’s 4th Green Chemistry Application and Innovation Award presented by the Ministry of Environment.

Traditional PU production relies on highly hazardous chemicals such as phosgene and isocyanates, posing significant risks to both human health and the environment. FENC challenged this conventional framework by developing AirTek PU, a CO₂-based non-isocyanate polyurethane technology that successfully eliminates the toxic substances while maintaining PU’s elasticity and performances. Compared to traditional thermoplastic PU, AirTek PU reduces carbon emissions by 58%, fully demonstrating sustainable carbon capture and utilization.

FENC® TOPGREEN® AirTek PU Production Process (Illustration Credit: FENC)

FENC® TOPGREEN® AirTek PU Production Process (Illustration Credit: FENC)

Guided by the principle of “high-value resource utilization and low-impact manufacturing,” FENC integrates carbon reduction, carbon fixation, and resource circulation throughout raw material selection, process design, and material structure. The process generates only ethylene glycol as a by-product, which can be reused in polyester production. The PU material itself is thermoplastic and recyclable, significantly enhancing material circularity and advancing true resource recovery.

TOPGREEN® AirTek PU is scheduled for capacity expansion in 2026 to meet global demand for low-carbon materials. Applications include footwear, synthetic leather, elastic fibers, waterproof breathable membranes, and potential extensions into medical and electronic sectors.

Far Eastern New Century continues driving material transformation through innovative technologies, strengthening product competitiveness, and collaborating with supply chain partners to promote green manufacturing, moving toward a low-carbon, non-toxic, and circular future.

Business and Company

News Type

UN SDG

Share

Source

Far Eastern New Century