Introduction of Everest Textile

Everest Textile was established in 1988 and is one of the few vertically integrated textile manufacturers from yarn, fabric weaving/knitting, dyeing, printing, and garment manufacturing. It is a smart textile company known for its innovation capability and sustainability. With the competence of a vertically

integrated textile manufacturer, from R&D, raw material, processing to final products, our mission is to fulfill customer’s needs and promote “safe apparels” through producing human and eco friendly textiles.

Everest Textile specializes in false twistin g yarn and eco innovation with the integration of functional fabrics used in sports, outdoor, and fashion. Striving to be the leading innovator in the textile industry, Everest established its first technology research center in 2003. With an annual invest ment of about 3%~4% of its total revenue, Everest technology research center transforms old fashioned physical manufacturing into chemical manufacturing. For environmental friendliness and cooperation with international brands’ sustainable environmental policy, we use recycled materials to produce and further make the development of other environmentally friendly materials such as solution dye, collagen yarn,

oyster yarn, and recycle spandex yarn. Furthermore, there are non fluorine water repellent processing fabrics that could be combined with smart production to reduce chemical usage. In recent years, the extreme climate has become a common climate type under global climate change, which has led to a significant increase in demand for composite functional textiles. We provide composite function products of filament fiber, staple fiber, and knit with a differentiated basis, and integrate innovation with other industries in the use of new material technology, which can demonstrate Everest's strong ability on high performance composite textiles.

Everest launched the vision strategy of “ Moons hot 5 + 5 Global Layout” in 2016, and ha d the courage to invest in the future, extending from the existing three Asian factories in Taiwan, China, and Thailand to the Americas and Africa, and adding a vertically integrated yarn weaving and dyeing factory in the United

States. And Everest also made good use of regional preferences of various countries to expand garment factories, cooperate with existing brand customers in advanced countries in Europe, America, and Japan in the short term, and expand the global emerging economy market in the long term, and make an early

layout for future sustainable operations . S o far, Everest has been added. North Carolina gauze dyeing factory, Haiti garment factory, and Ethiopia garment factory , which can provide Everest's main markets For example, one stop service for brand customers in North America and Europe, can also expand to emerging markets and second tier brand customers. Everest o perat es in the local market to expand revenue . I n the future, we can respond to the growth opportunities in the African and Central and South American markets and achieve local to local, time to market local production, local sales, and a green economy with the lowest carbon footprint.

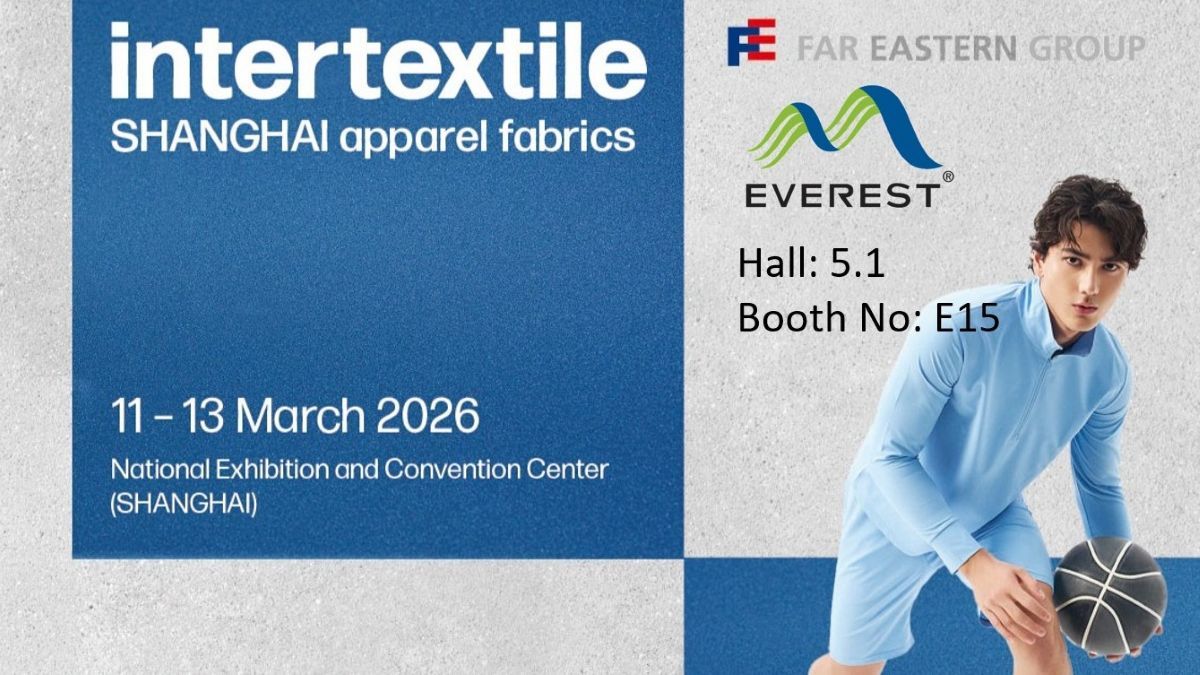

The logo bears resemblance to Mt Everest, the highest mountain in the world, to show the corporate spi rit to reach the summit and to be best of

The logo bears resemblance to Mt Everest, the highest mountain in the world, to show the corporate spi rit to reach the summit and to be best of

the best. It also symbolizes Everest’s spirit of moving forward and reaching to the top with persistence and disruptive innovation. The new core value of the “Everest People” is to challenge the limit to keep growing. The blue and green used in the logo are two colors that are strongly associated with the concept of eco friendliness in Europe, Ame rica and Asia, which constitute s Everest’s eco enterprise model.

Business and Company

News Type

Share

Download

Source

Everest 2019 CSR Report