Textiles - the Origin of FEG

Far Eastern's textile factory moved from Shanghai to Banqiao after the Government retreated to Taiwan in 1949. The Company provided warmth with basic needs such as the manufacturing of the "Skyscraper" brand of knitwear. Later, in touch with Taiwan's economic pulse and government initiatives, the Company redirected its business accordingly, from producing petrochemicals and fibers to spinning, weaving, dyeing, and retail, it has created a complete supply chain.

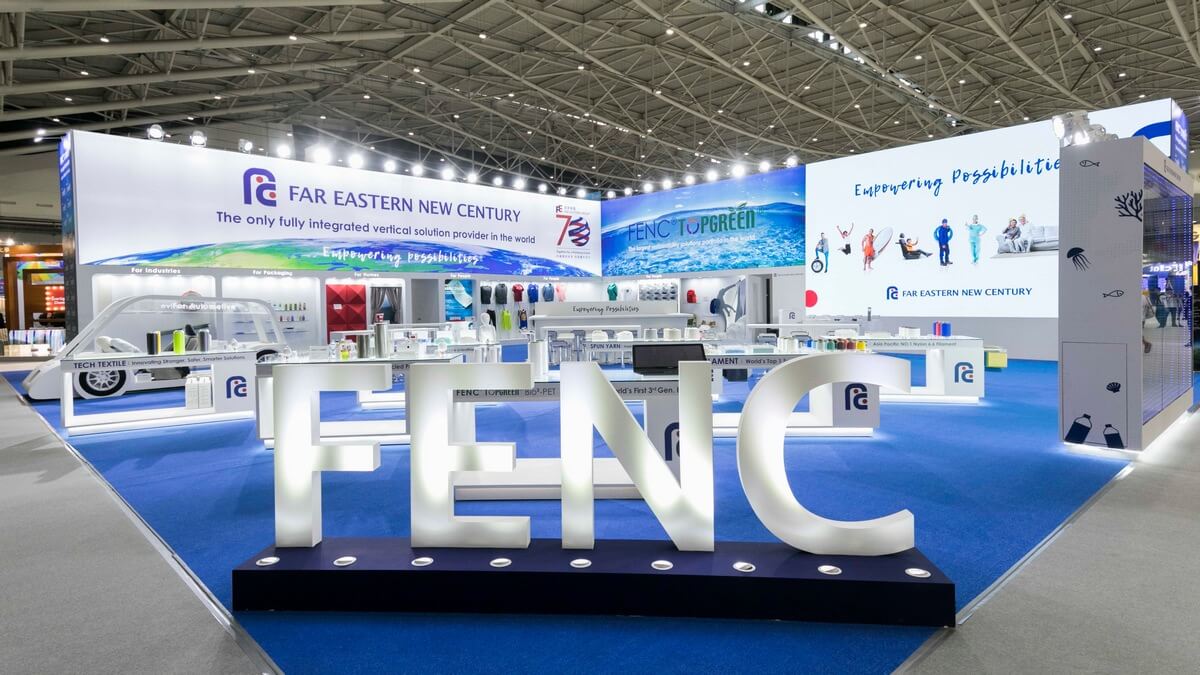

Awareness of Far Eastern Textile Ltd. (FETL) was limited to garment manufacturing, however, in its present incarnation as Far Eastern New Century Corporation (FENC) the company business has grown and touches upon all aspects of daily life in Taiwan.

Far Eastern New Century Corporation (formerly Far Eastern Textile Ltd.)’s early printed fabric products hold beautiful memories for the people of Taiwan.

When the Nationalist Government retreated to Taiwan in 1949, Far Eastern’s textile factory moved from Shanghai to Banqiao, Taiwan. During that period, daily necessities were scarce and the company provided warmth with such basic needs as the manufacturing of the “Skyscraper” brand of knitwear. FENC set many records in Taiwan’s textile industry, for example, it was the first to export cotton yarn as well as apparel overseas. The Group served as a key generator of foreign exchange reserves for Taiwan, contributing directly to Taiwan’s economic prosperity.

In touch with Taiwan’s economic pulse and government initiatives, FENC redirected its business accordingly. When the company suffered from a raw material shortage, it seized the opportunity to expand vertically from upstream to downstream. From producing petrochemicals and fibers to spinning, weaving, dyeing, and retail, it has created a complete supply chain and to this day in Taiwan, only Far Eastern Group has successfully accomplished this.

Johnny Shih, Vice Chairman of FENC, has pointed out that the company’s development can currently be divided into three phases. The first phase focused on quality and quantity of mid- to downstream products. In the second phase, the company shifted its focus from textiles to non-textile applications and producing value-added products such as PET bottles, High Tenacity Yarn, tire cord and optical film. Petrochemicals were later developed, to become a core product offering. The third phase is more focused towards becoming a leading global supplier with high-quality innovative products.

According to Eric Hu, Senior Executive Vice President of FENC’s Textile Business Operation Center, “A business needs innovation to move in step with global trends.” Innovation should cover customer base, product and manufacturing processes. “We are sensitive to who our customers are and their needs. We work with leading brands such as Nike and Adidas. These companies are less affected by economic downturns and therefore we are less affected.” Furthermore, FENC also collaborates with emerging companies such as Uniqlo from Japan, A&F from the United States, and LI-NING from China. Mr. Hu emphasized that FENC is among the top few suppliers avoiding elimination from key accounts.

FENC has a raw materials research advantage, giving the company a great deal of flexibility in apparel innovation. The product varieties have shifted from basic knitwear, to fashionable sportswear. FENC is now a major supplier of China apparel brands, leading China’s apparel industry into a more streamlined manufacturing process. Austin Lee, President of Far Eastern Apparel (Suzhou) Co., Ltd. in China, indicates that the lead time from template preparation to final product can be shortened from one week to one day on diverse projects.

The success of the cross-strait deployment between Taiwan and China has increased FENC’s scale, and brought energy and momentum to the company. Eric Hu believes that a company needs to grow constantly. “By capacity expansion and talent development, the company will be able to attract new talent, international customers and global investors. “

“You can see the true potential of a business by how it handles crisis.” Mr. Hu lamented about the first energy crisis back in 1973. In three years, 70 percent of the downstream textile companies in Taiwan had closed, and FENC was greatly impacted as well. But facing the 2008-2009 global economic crisis over 30 years later, FENC had the foresight to be cautious with all investment projects, and enhanced the management of our financial measures. This shows that the company has the ability to shrug off major impacts of the economic crisis with its abundant experience and solid tradition of “Sincerity, Diligence, Thrift and Prudence.”

Business and Company

News Type

Share

Source

60th Anniversary Book - Economy